Mention SWOT (Strengths, Weakness, Opportunities, Threats) analysis in a meeting these days and watch experienced employees look away and the newer members look puzzled. SWOT analysis, once touted as a corner stone of corporate strategic planning, has now been relegated to useless think tank dribble. It is true that SWOT analysis can oversimplify the corporate situation by forcing a classification of factors into one of four rigid categories in the quadrant. Nevertheless… SWOT analysis is still useful for reducing a large number of situational factors into a manageable profile for high level assessments.

So what can SWOT Analysis to help improve processes?

For operational excellence professionals, SWOT can be a very good tool for addressing such root causes as lack of awareness, misunderstanding, no sense of urgency, no compelling reason to change, addressing the ‘what is in it for me’ syndrome, and conflicting interests & priorities. Of course, these root cause are manifest in different behaviors, most commonly active resistance, delayed or no decision, missed meetings, orchestrated delays, false starts, passive resistance, vocal skepticism, disengaged team members, missed assignments and so forth.

How do I use SWOT Analysis for Process Improvement?

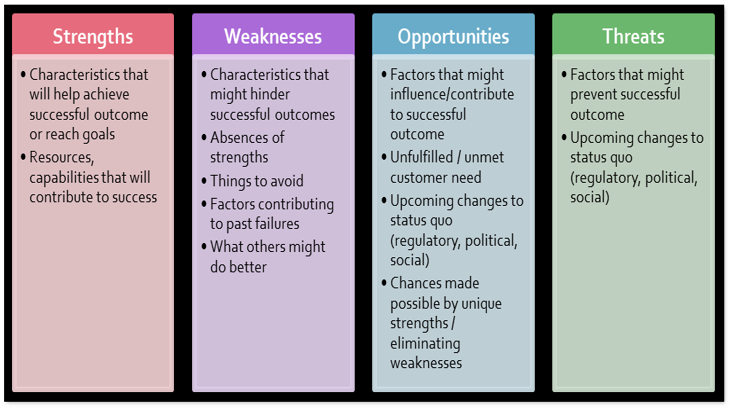

Let’s take a brief look at SWOT analysis. It consists of four components: Strengths, Weaknesses, Opportunities & Threats. First identify strengths of the process, people and products as it relates to the improvement initiative. These are both tangible and intangible factors; not situational strengths but rather factors over which you control. The key here is ‘control’ and means internal factors. It usually means internal to the organization but when improving processes, it can be internal to a business unit, department, geographic location, etc.

Next, and in a similar fashion, look at the weaknesses of process, people and products. Weaknesses are factors that are within your control that detract from delivering value without significant waste. Ask: why are we doing this project?

Now switch to the opportunities. What is the targeted improvement? What opportunity are you trying to seize? Why are you doing this now? These questions will help identify the key opportunities. In the traditional SWOT, the opportunities portion of the analysis usually refers to external opportunities. In process improvement initiatives, it can be this or internal opportunities as well.

And last . . . address the threats. Ask: what will happen if this process (or product) is not improved. What will be, or has been, the consequences of not improving the situation. Be specific and as detailed as possible. This also is traditionally external threats but as with the opportunities, it can be this or internal threats to the organization.

Ideally, the people who resist, delay, won’t make a decision, miss meetings, etc. would be involved in developing the SWOT. Being part of the process always helps with but-in. If they are not part developing the SWOT analysis, once it is complete, use it as a communication tool to get the buy-in needed.